ME 102B: Design of Mechatronic systems

Fall Semester 2013

For the mechanical engineering senior design project, our team decided to construct an auto-correcting CNC router Sharpie artist.

Motivation: The maximum part size for traditional CNC machining is determined by the size of the CNC gantry. Instead of creating larger CNC stages to machine larger parts, this problem can be circumvented altogether by combining a smaller CNC stage, relevant sensing to determine the position and orientation of the stage, and a source of coarse external actuation.

This idea can be implemented in many CNC applications, including laser cutting and 3D printing. In this project, we will apply this idea to 2D routing/drawing.

Solution overview: Four rollerball mice are mounted to a 2.5 axis CNC gantry with ~2" of play in the primary axes. External actuation is provided by a human operator.

A toolpath is loaded onto the device, and a GUI guides the operator to follow the rough position of the toolpath. The device senses its position and orientation using the four rollerball mice, and actuates the small gantry to fine tune the operator’s motion.

Team Members: Rahil Mehta, Jonathon Wang, Gi Youn Lee, Samuel Yoon

My Responsibilities: electrical design, mechanical design and fabrication of sharpie magazine, some traditional machining for the CNC stage, microcontroller programming.

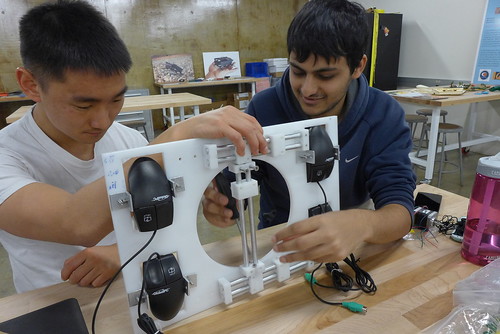

Our 'high precision dual channel optical encoders'(rollerball mice) mounted onto the base.

Initial tests of position tracking with rollerball mice.

Preliminary machining. Delrin blocks and aluminum rods for the two axis gantry, motor mounts, brackets for the mice.

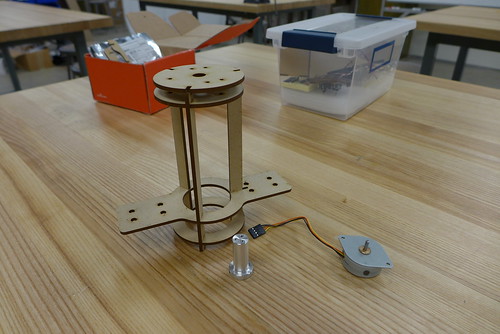

Instead of purchasing an off the shelf router, we decided to use the autocorrecting CNC gantry to draw with retractable Sharpie markers. This assembly can cycle through three different colors by rotating the pens across a stationary cam using a stepper motor.

Simplified Sharpie holder used in the final demo. During the last week of the project, I transitioned to helping the team with microcontroller programming.

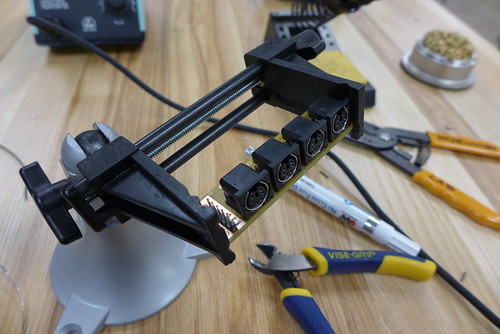

I designed two circuits for this project: one to act as a hub for our four rollerball mice, and one to drive the stepper motors.