Microcantilever-bending measurement of Young's modulus. In any microsystems design employing a film, knowledge of that film's mechanical properties, especially its elastic modulus, is usually crucial. The importance of measuring Young's modulus of micron-thickness films has given rise to an array of testing methods. Among the simplest is the deflection of a cantilever beam fabricated in the film of interest. Deflections in response to a known load are interpreted using a structural model of the cantilever. The beam might be deflected by scanning a stylus profilometer from the root to the tip of the cantilever: this is the approach that I investigated in my 2004 M.Eng. project. Alternatively, the cantilever can be depressed with a nanoindenter positioned at a particular location, or series of locations: this is the approach for which I developed new data-analysis procedure while a teaching assistant for the Micro- and Nano-Fabrication Laboratory in 2006. Deflecting the beam at a series of at least two precisely separated locations allows us to compensate for the effect of any parasitic under-etching of the root of the cantilever.

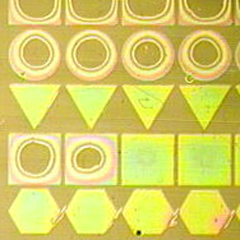

Measurement of the toughness of plasma-activated polymer-polymer bonds. I have invented a micro-crack-opening method for measuring the work of fracture of bonded polymeric interfaces. The method is compact, quick, and non-destructive, and allows the erosion of bond toughness to be measured, if desired, over many months. By arraying micro-cracks over a bonded area, any spatial variation of bond toughness can be identified. Preliminary use of the method to test alternative pre-bonding surface treatments is described in this poster.