This is a core, required undergraduate class for mechanical engineers. It introduces students to the capabilities of a range of manufacturing processes, provides a foundation in tolerancing concepts, and teaches the key aspects of 2D and 3D sketching and technical drawing. Geometric dimensioning and tolerancing standards are covered and practiced. The class's lab sessions include reverse-engineering of manufactured products, live demonstrations of manufacturing processes, numerical process simulation exercises, field trips to local manufacturing companies, and an eight-week-long conceptual design and prototyping project where students use the makerspace in the Jacobs Institute for Design Innovation to realize their team's design. Moreover, all students taking Engineering 29 are entitled to be trained in the Mechanical Engineering Student Access Machine Shop and to use it for project realization. A syllabus for Engineering 29 is here. An article about the teaching of design and manufacturing in the Jacobs Institute is here.

I am more convinced than ever that it is right for us to emphasize this material in the first half of the ME undergraduate curriculum, given the societal and economic importance of manufacturing. Moreover, many conversations with students over the years have shown that an understanding of geometric dimensioning and tolerancing and an ability to interpret and create technical drawings are crucial skills that unlock both internships and full-time job opportunities.

Engineering 29 was introduced in Spring 2021 using a syllabus that I designed with colleagues. It integrates content from two now-retired courses: Engineering 27 (which I originally implemented in 2015 and taught for six years), and Engineering 25, a course on engineering graphics.

This one-unit class provides a program of visits to local manufacturing companies. In our busiest semester we took students to more than 15 facilities in the Bay Area, including a large metal-casting foundry, a sheet metal processing facility, and an innovative building prefabrication company. Students particularly value these opportunities to see manufacturing processes in action, make connections with professional engineers, and scope out potential internships.

Des Inv 97 builds upon the practice that I had instituted of organizing field trips for Engineering 27 and ME122 students. The creation of a dedicated course number provided a platform for students to gain credit for the additional effort inherent in attending trips, enabled students from other departments to participate in trips more easily, and unlocked administrative and teaching support from the Jacobs Institute, as well as some funding for transport. Credit is obtained in Des Inv 97 by attending at least five visits and writing a reflective piece about one or more of the visits.

This course introduces mechanical engienering undergraduates to electronic circuit theory and analysis techniques, digital logic principles, microcontroller programming, and sensors and actuators. It culminates in a project to design and prototype an internet of things application, blending sensing, computation, and actuation to perform a useful function.

I taught this class in Fall 2020 during a period of fully-remote learning. To provide the best possible remote experience for the students, I collaborated with colleagues to develop an enhanced microcontroller lab kit that students could use at home (see "Microkit taskforce" below). My approach was to try to integrate the circuit theory elements of the class more closely with the labs than had previously been the case. I developed the lab kit to include a wider range of discrete components, and supplemented the Microkit with a handheld oscilloscope to replicate the in-lab experience to greatest extent possible. I introduced several new lab assignments in which students built and probed the operation of simple circuits (e.g., RLC oscillators) that illustrated concepts from the class. I also added a lab in which students experimentally evaluated the accuracy with which Bluetooth signal strength values could be used to estimate the proximity of another device. This lab combined practical programming skills with an appreciation of the physics of radio transmission which we had introduced earlier in the course. It was particularly topical, since at the time smartphone apps were being rolled out that used Bluetooth signals for Covid contact tracing. The syllabus is here.

I chaired this ME Department taskforce in Spring 2020, to develop a microcontroller kit that could be distributed to students taking three of our core laboratory classes: ME100, ME102B (mechatronics) and ME103 (instrumentation). The kit needed to support entirely home-based learning during the pandemic, but also to enrich learning once students returned to campus. Designing the kit involved working with colleagues to carry out a meticulous survey of the teaching needs in these classes, as well as casting the net wider to understand whether any other courses in the Department would benefit from using the kit. After writing the task force report in July 2020, I then finalized the bill of materials for the new kit, identified best-value sources for the components, and coordinated with technical staff to design a distribution system that combined in-person pickup by on-campus students and shipping to remote students.

To support use of the kit, I initiated a companion website which describes the contents of the kit and provides getting-started guides for the Micropython and Arduino programming platforms as well as some key circuit designs. This website was developed by graduate student Andrew Barkan. With the rest of the Microkit team, I received an Extraordinary Teaching in Extraordinary Times award from the campus in April 2021 for this work.

This is an junior-/senior-level undergraduate elective in which students analyze and learn about the capabilities of a wide range of manufacturing processes, and practice selecting processes and materials in a coherent way for a given engineering application. The centerpiece of the class is a semester-long project in which students work in teams to conceive and design a mechanical device, and then carry out a rational selection of materials and manufacturing processes for its key components. An example of particularly successful past project is a portable hydro-turbine. A syllabus is available here.

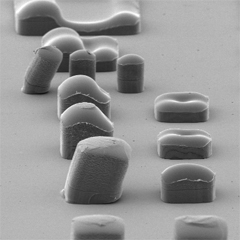

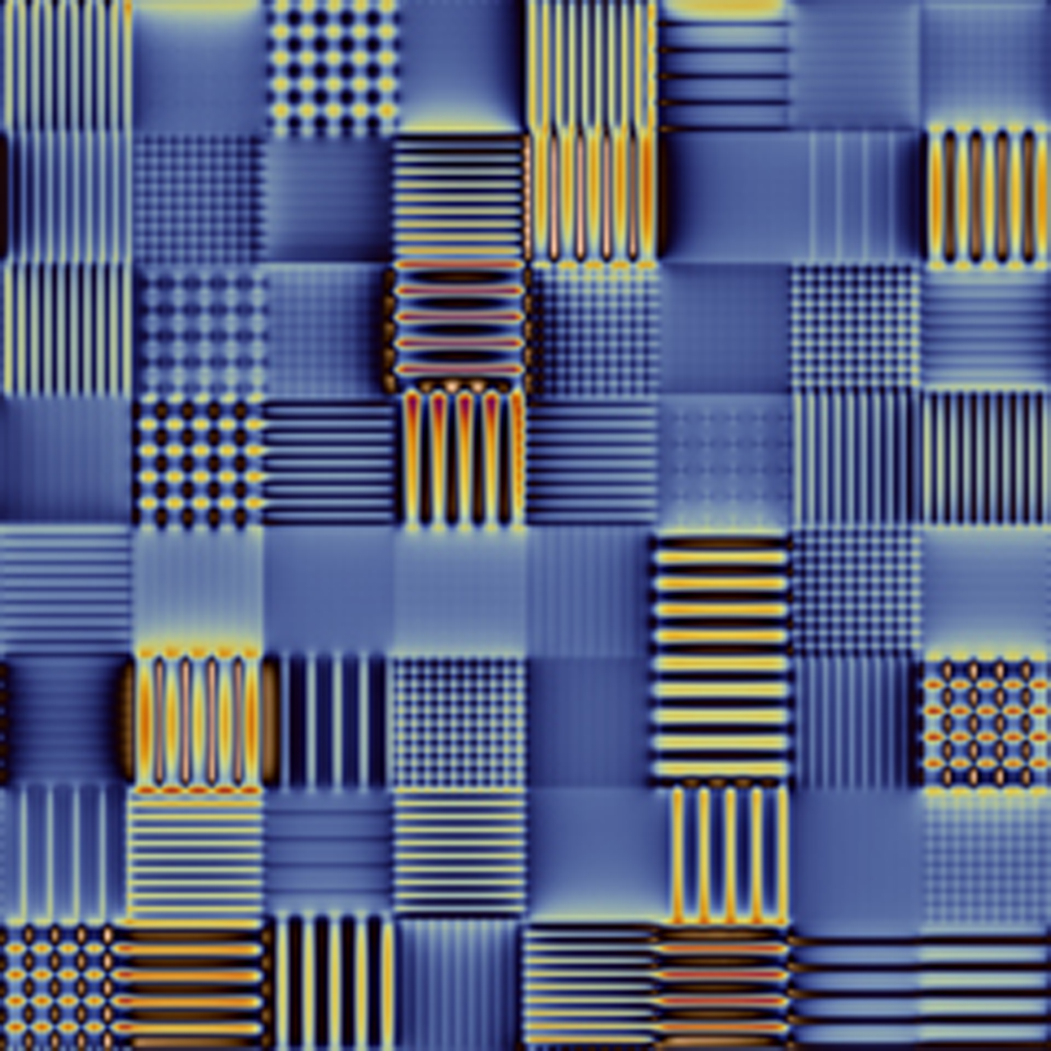

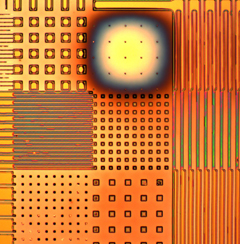

My signature graduate elective surveys sub-micrometer pattern-transfer techniques with applications in semiconductor manufacturing, data storage, photonics, and surface engineering. Lectures introduce the optical and mechanical principles underlying a spectrum of candidate lithography techniques, and show extensive examples of industrial applications. Students read journal papers in the field, write "peer reviews" of these papers, and then discuss their reviews in class. The course culminates in team projects, for which students are invited to propose a new lithography process, to model and simulate an under-studied phenomenon in an existing process, or to survey the state of the art in a particular area of lithography. A syllabus is available here. I previously offered this course as Mechanical Engineering 290R: Topics in Manufacturing: Lithography.

My other teaching activities have included developing, with video producer Loi Almeron, a video-based orientation on lathe turning to streamline training in the Mechanical Engineering Student Access Machine Shop. This project was funded with a UC Berkeley Instructional Improvement Grant.

Control of Manufacturing Processes (Spring 2008). I was the graduate teaching assistant for this graduate-level elective class. Class materials available from MIT's OpenCourseWare website.

Micro-and Nano-Fabrication Laboratory (Fall 2006). I was graduate teaching assistant for this class. I devised new data analysis procedures for the microelectromechanical systems (MEMS) and microfluidics laboratories, and enhanced the student manual for the microelectronics laboratory.

Quantitative Physiology: Cells and Tissues (Fall 2007). I was graduate teaching assistant for this class. Class materials from an earlier term (for which I was not a teaching assistant) are available from MIT's OpenCourseWare website.